Understanding Chain of Custody in Supply Chain Management

- Lyat Avidor Peleg

- Nov 2, 2023

- 6 min read

Updated: Jun 16, 2024

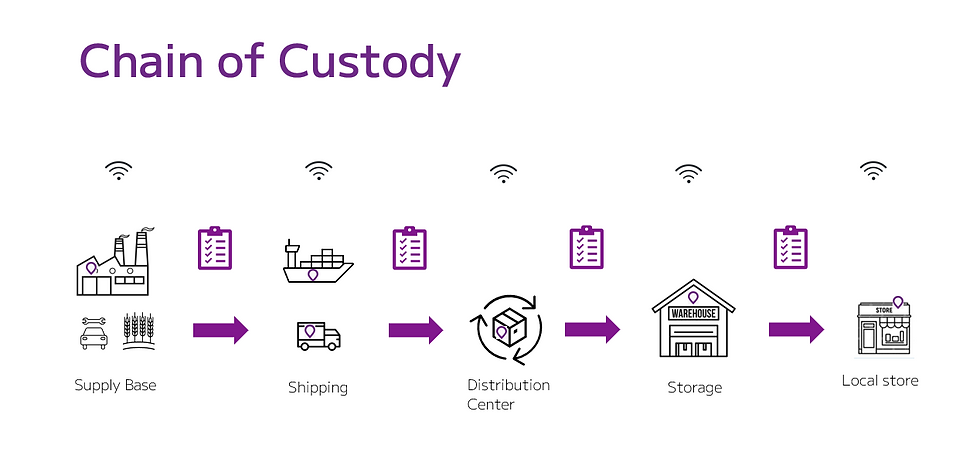

Chain of custody refers to the process of tracking a product from its initial source as raw materials through to its final destination, whether that is the end user or retailer. A product can go through many stages before it is complete, including sourcing, production, processing, shipping, and retail.

Chain of custody is a crucial part of supply chain management, ensuring quality control and safety. Explore its risks and benefits, and how to create a chain of custody.

Table of Contents:

How to Create a Chain of Custody Process

Definition and Importance of Chain of Custody Tracking

Chain of custody tracking is the systematic monitoring and documentation of a product's movement throughout the supply chain. It involves recording important information such as origin, destination, custody transfers, and handling procedures, establishing a verifiable trail of custody.

Chain of custody tracking is critical for several reasons:

Compliance and Regulations: Many industries have strict regulations dictating product handling, storage, and transportation and chain of custody records demonstrate compliance with these requirements.

Quality Control and Assurance: By tracking a product's journey, you can identify potential quality issues early on, allowing corrective actions to be taken before problems escalate.

Risk Mitigation: Knowing a product's location and history allows you to pinpoint vulnerabilities and implement strategies to safeguard your inventory.

Traceability and Accountability: Product recalls, quality concerns, or supply chain disruptions can happen. If they do, a comprehensive chain of custody allows you to take quick corrective actions and minimize potential harm.

Key Components of the Chain of Custody Process

To create this chain of custody effectively, a company needs to ensure its process has these essential components::

A Logistics Strategy: A clear idea of which items need to be tracked.

Tracking Technologies: Advanced tracking technologies such as RFID tags and IoT sensors to enable real-time monitoring and tracking of product movements throughout the supply chain.

Documentation and Record-Keeping: This includes systems for capturing detailed information about each product's origin, handling, storage conditions, transportation routes, and custody transfers.

Standard Operating Procedures (SOPs): SOPs for handling, packaging, labeling, and transporting products ensuring compliance with established protocols.

Auditing and Compliance Checks: Regularly review the entire process to look for areas of improvement and ways to increase efficiency.

Trained Employees: Designate employees responsible for managing each step of the process, and ensure they are well-trained and fully capable.

Supply Chain Risks Associated with Chain of Custody

Some of the key risks associated with inadequate chain of custody management include:

Physical Damage to Products: Without accurate tracking and monitoring, companies may struggle to quickly identify how and when damage is occurring and address these causes.

Loss or Theft of a Component: Lack of visibility and control over product movements increases the likelihood of theft or loss incidents going undetected.

Missed Deadlines: Without real-time visibility and accurate information about products’ locations, companies may struggle to meet customer demand and fulfill orders efficiently.

Human Error: Misplaced parts, incorrect inventory counts, or erroneous documentation can create confusion and complicate supply chain operations.

Difficulty in Scaling: Inadequate chain of custody processes may hinder scalability efforts, making it challenging for companies to effectively manage larger amounts of inventory and meet growing demand.

Threats to Chain of Custody Integrity in Supply Chains

Counterfeit Products: Without proper authentication and traceability mechanisms, supply chains are vulnerable to counterfeit products entering the market.

Tampering and Contamination: Unauthorized tampering or contamination of products during transit or storage can compromise product quality, safety, and regulatory compliance.

Data Security Breaches: Inadequate security measures for storing and transmitting chain-of-custody data increase the risk of data breaches, exposing sensitive information to unauthorized access.

Consequences of Chain of Custody Failures

Loss of Customer Trust and Loyalty: Chain of custody failures can erode customer trust and confidence in a company's ability to deliver products reliably and securely, resulting in lost sales, damaged reputation, and diminished brand loyalty.

Legal and Regulatory Penalties: Non-compliance with regulatory requirements or industry standards regarding chain of custody management can result in fines, sanctions, and legal consequences.

Supply Chain Disruptions: Chain of custody failures can disrupt supply chain operations, causing delays, inventory shortages, and production disruptions.

Benefits of Chain of Custody in Supply Chains

The biggest benefit of chain of custody is constant knowledge and visibility into where products are located. This knowledge enables managers to manage the entire process more efficiently. Other benefits include:

Transparency - a fully transparent supply chain means a lower risk of theft or other compliance breaches.

Quick Resolution of Problems - potential challenges can be identified early and resolved quickly before causing unnecessary delays and expenses.

Targeted Recalls - knowing exactly where each component is and has been means being able to identify which specific products should be involved in a recall should there be a defect. Only recalling what is absolutely necessary is much less costly and less of an inconvenience to customers than recalling a wider range of items.

Ensuring Product Integrity and Quality Assurance - by accurately tracking and documenting the movement and handling of products, companies can maintain strict quality standards, and prevent contamination or tampering.

Legal Compliance and Risk Mitigation with Chain of Custody Documentation - with a verifiable record of compliance with industry standards, regulatory mandates, and contractual obligations, companies can mitigate legal risks and demonstrate due diligence.

Future Trends in Chain of Custody Technology

As supply chains become increasingly complex, technological advancements are enhancing chain of custody tracking and management.

Innovations Shaping the Future of Chain of Custody Tracking Systems

Blockchain Technology allows immutable documentation to be created, preventing any tampering with records.

Artificial Intelligence (AI) and Machine Learning allow businesses to analyze vast amounts of data, identify patterns, and predict potential disruptions or anomalies in chain of custody operations.

Digital Twin Technology enables companies to create virtual replicas (digital twins) of products, processes, and supply chain networks. By simulating and analyzing various scenarios in a virtual environment, organizations can optimize chain of custody processes, test alternative strategies, and enhance resilience against unforeseen events.

Predictive Analytics allows companies to leverage historical data and real-time insights to forecast future trends, demand patterns, and potential risks in chain of custody operations. Companies can then direct and optimize resources, minimize disruptions, and enhance supply chain agility.

Automation technologies, such as robotic process automation (RPA), streamline repetitive tasks, and manual processes in chain of custody management. Automated systems can accelerate data collection, documentation, and verification processes, reducing errors, and improving overall operational efficiency.

How Deeyook Can Help

Deeyook’s precise location-tracking capabilities can provide complete visibility throughout the entire supply chain, allowing for a complete and unbroken chain of custody. No matter how many steps a product must go through to reach its final destination, Deeyook offers real-time, accurate location information.

How Deeyook Utilizes Chain of Custody Tracking Solutions

Deeyook takes a unique approach to asset tracking by leveraging the power of existing Wi-Fi infrastructure with a unique combination of interferometry and AI-based models. Deeyook’s approach includes:

Plug-and-Play Tracking - wireless-enabled soft trackers seamlessly connect to the Deeyook Tracking Suite for real-time location tracking without adjusting existing Wi-Fi setups.

Passive Sensing Technology - trackers passively use Channel State Information (CSI) signals emitted by any Wi-Fi Access Point (AP), eliminating the need for specific AP configurations or permissions.

Flexible Deployment - allows you to use any existing AP, even those not owned by the site, as long as the signal strength meets the minimum requirement.

Connectivity Options - various connectivity options, including a dedicated Deeyook SSID, use the site's connectivity.

The Benefits of Deeyook's Chain of Custody Management Services

Enhanced Visibility and Transparency

Deeyook enables companies to monitor product movements, identify potential issues, and make informed decisions to optimize efficiency and mitigate risks.

Improved Security and Compliance

By maintaining accurate records of chain of custody activities, Deeyook helps companies mitigate the risk of theft, fraud, and regulatory non-compliance.

Streamlined Operations and Cost Savings

Deeyook helps companies achieve greater operational efficiency and cost savings, ultimately driving bottom-line growth.

Proactive Risk Management

Deeyook helps companies anticipate potential disruptions, such as delays, shortages, or quality issues ensuring continuity and resilience in supply chain operations.

Start your journey to cutting-edge supply chain management by contacting us today.

FAQs

Q: What is the chain of custody process?

A: The chain of custody process refers to the systematic documentation and monitoring of product movements and handling procedures throughout the supply chain, from origin to destination. It involves maintaining a verifiable trail of custody to ensure transparency, accountability, and compliance with regulatory requirements.

Q: Why is chain of custody tracking important in supply chains?

A: Chain of custody tracking is important in supply chains because it enhances transparency, security, and compliance, mitigates risks, and enables efficient management of product movements. By maintaining accurate and auditable records of chain of custody activities, companies can optimize operations, reduce costs, and enhance customer satisfaction.

Q: What are the risks associated with chain of custody failures?

A: Chain of custody failures can lead to various risks, including product damage, loss, theft, missed deadlines, compliance breaches, and supply chain disruptions. Inadequate chain of custody management may result in financial losses, legal liabilities, and damage to brand reputation.

Q: What benefits does chain of custody provide in supply chain management?

A: Chain of custody provides several benefits in supply chain management, including enhanced visibility, transparency, security, compliance, operational efficiency, cost savings, and risk mitigation. By maintaining a complete and unbroken trail of custody, companies can optimize supply chain operations and deliver superior customer experiences.

Related Resources:

Watch Webinar: Asset Tracking to Maintain Complete Chain of Custody

Watch a brief recap of the webinar: Asset Tracking to Maintain Complete Chain of Custody